Flotation column is a kind of new, efficient and energy-saving flotation equipment without mechanical aeration mixing equipment. As the name implies, its tank is column shaped, and its long diameter ratio could be 6 〜10 times. In the early 1960s, Canadian chemical workers and Telib invented the flotation column. In 1963. it won the Canadian chartered patent. Since the mid 1960s abroad, due to the confinement of "force of habit", flotation column has developed in a standstill state. It is not until the late 1980s that there has been greater progress.

Flotation Column Description

Domestically, in 1965. Metallurgy Ministry held a Spot Conference of Flotation Column in North Ore Department, calling on the mines nationwide to study and to apply this new technology if condition is allowed. Thus, in the late 1960s, there are altogether 30-40 different types of concentration plants that use flotation column in the production. It could be said that the earliest and most frequent use of flotation column is in China. However, as a result of a low degree of automation condition of flotation column aeration quantity and level control, the control is rather difficult. The micro foam generator is easy to be blocked and the operation is inconvenient with a lack of experience. Therefore, it is unable to display its superiority and is strangled in the cradle. With the coming of the new century, computer is widely used in all walks of life in China. The rapid development of industrial automation and continuous improvement of pneumatic mechanism carry forward its deeply hidden superiority for long. It is not limited to the fine concentration only, but has now expanded to the roughing, scavenging, and other industries. There have also been whole-flotation column beneficiation plants overseas. The minerals it processes includes copper, lead, zinc, molybdenum, nickel, manganese, iron, white tungsten, coal, fluorite, barite, graphite, talc, apatite and other minerals. Its range of application, with the accumulation of experience and scientific development, expands with each passing day.

Compared with floater, the flotation column boasts the following advantages: better operation and control; higher recovery rate of fine particles; less mechanical inclusion and higher concentrate grade; ability to operate under a high slurry concentration; suitable to be controlled by computer; higher foam enrichment ratio; smaller area with no moving parts. It saves energy, land, investment, and repair costs, with an expansion of capacity compared with the old plant. It has an obvious economic benefit with a wide prospect of application.

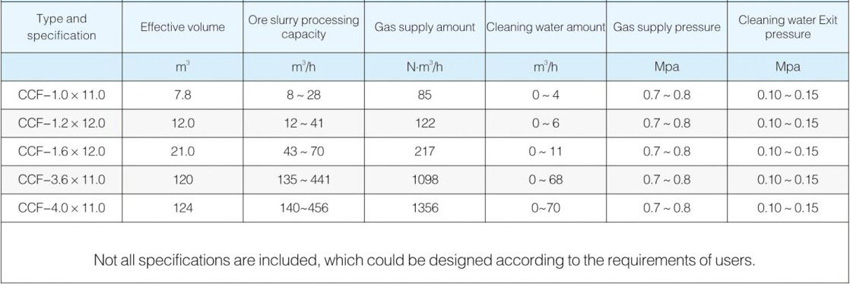

Main Technical Parameters