Gold is the special currency for the investment and reserve, and it is even an important industrial raw material for jewelry, electronics, aerospace and other industries. With the rapid development of industry and finance, the gold processing has been paid close extensive attention and developed rapidly.

With the decrease of the ore grade, the demands for gold ore dressing technology is increasing gradually. In recent years, new process, new technology and new equipment are constantly being applied in the gold ore processing, which promotes the gold ore dressing process and production index.

Zhejiang Golden has been committed to the research and development of gold ore dressing technology and equipment for 50 years and possessed rich project experience, who can provide you with reliable equipment and technical services. Let’s see Zhejiang Golden by combining the following several common gold ore dressing processes.

1. Gravity Separation

Due to the large proportion of gold ore, gravity separation is the most common method for gold recovery, and it is often used to deal with all kinds of gold ores with other mineral processing methods. Sand gold is separated by gravity separation process mostly.

In the gravity separation plants, the common gravity separation equipment includes shaking table, jig and spiral chute.

2. Cyanidation

Cyanide leaching is one of the main methods for gold recycling. It has advantages of high recovery rate, strong mineral adaptability and in-place gold producing, so it is widely used in gold processing. Cyanide leaching can be divided into two types: tank leaching (agitation leaching) and heap leaching (percolation leaching).

Tank Leaching

Agitation leaching: After the grading and classifying, the pulp becomes the appropriate concentration through the thickening and dewatering, then add cyanide solution to mix, then enter to leaching.

Heap Leaching

Stacking low-grade gold ore on the anti-seepage foundation, then using the low concentration of alkaline cyanide liquid to spray the ore heap, dissolving the gold ore. The gold bearing solution infiltrates from the ore heap, then using the activated carbon adsorption or the zinc powder exchange precipitation to recover the gold.

The leaching process is divided into spray leaching and dripping leaching.

Spray leaching: the nozzle sprays the solution (sent by the piping system) to the air, which forms the raining effect then scatters the space of the ore heap.

The dripping leaching system on the customer’s spot is similar to the dripping device that used in plant irrigation, which falls down within a short distance and small area.

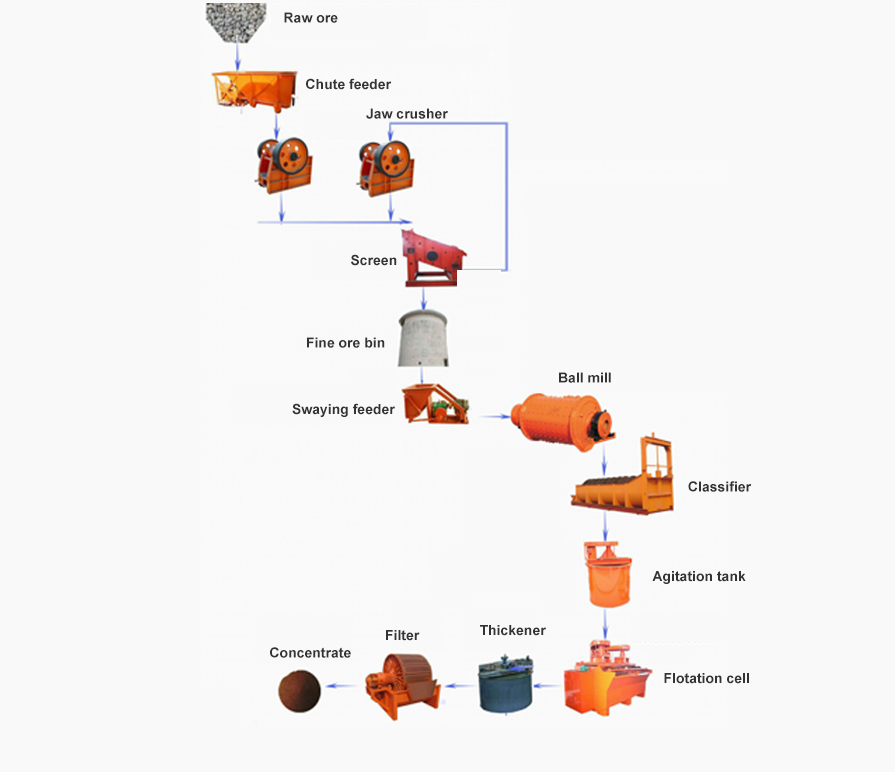

3. Flotation Process

Flotation process is widely used to deal with all kinds of gold ores. Usually, it is applied in the high float ability sulfide containing gold ore.

The flotation process can maximum concentrate the gold into sulfide mineral concentrate, so as to abandon the tailings early and reduce the ore dressing cost. In addition, the flotation process often used to deal with the multi-metal ore, realizing efficient and comprehensive utilization of mineral resources.

In practical production, we often determine the best gold process according to the experiment, it is maybe the single gravity separation, cyanidation and flotation process, or a joint process.

At present, with the encouragement of the increasing demand and rising gold prices, the promotion and application of new technology and the new process will continue to be developed.